MENUMENU

TALK TO AN EXPERT

Special Hours: 7AM – 6PM PST

TALK TO AN EXPERT

Special Hours: 7AM – 6PM PST

Transformerless inverters are showing up in more high-powered systems than ever before. In the past, you didn’t really have a choice—serious off-grid, RV, or marine setups almost always used heavy, transformer-based models. Now, new technology has opened the door to lighter, smaller, and often cheaper transformerless designs that can rival the old workhorses in many ways.

So, should you choose this newer approach? The benefits are real: less weight to haul, easier installation, and higher efficiency. But there are trade-offs, especially in safety, longevity, and durability, that you need to understand before deciding.

This article breaks it all down, from efficiency and surge handling to grounding, isolation, and long-term reliability, so you can make the right call for your system.

A transformer-based inverter (also called a low-frequency (LF) inverter) uses a large, heavy iron-core transformer running at 50 or 60 Hz.

The inverter first converts battery power (DC) into low-voltage AC. For example, 12 volts DC from your RV or boat batteries becomes 12 volts AC. The transformer then steps it up to 120 or 240 (230 in Europe) volts AC for your appliances.

The transformer also creates galvanic isolation. That means there’s no direct electrical connection between the battery side and the AC output. This improves safety, protects against electrical faults, and allows straightforward neutral-to-ground bonding.

LF inverters have been around for decades. They’re known for toughness, reliability, and excellent surge power for starting motors and pumps. The trade-off? They’re big, heavy, and usually less efficient than newer designs.

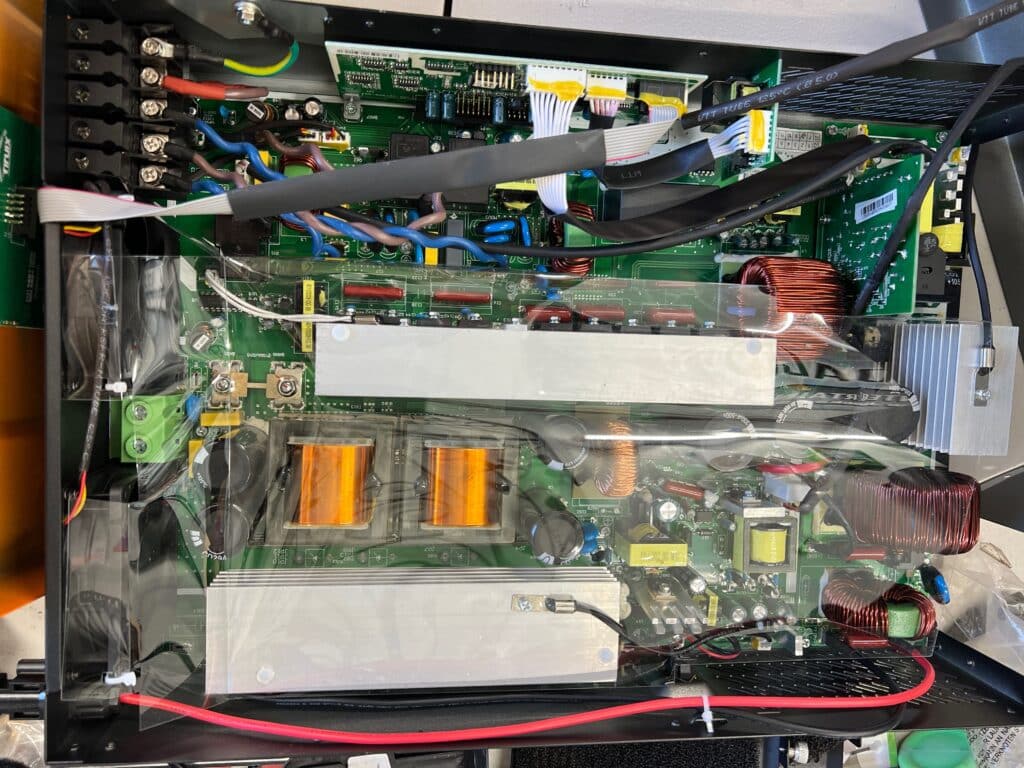

Transformerless inverters (or high-frequency (HF) inverters) skip the big, heavy transformer. Instead, they use advanced electronics to change DC to AC. Some have small high-frequency transformers for voltage boosting or filtering, but they don’t include a full-size 60 Hz transformer for primary voltage conversion.

HF inverters use high-speed semiconductor switches and smaller magnetic parts. This makes them far lighter, smaller, and often cheaper to build. They also achieve very high efficiency, often 95–98%.

Most transformerless inverters are non-isolated, meaning the DC and AC sides are directly connected through the electronics. This saves weight and space but changes how grounding and neutral bonding work.

It’s worth noting: “transformerless” doesn’t mean zero magnetics. Almost every inverter still uses inductors or small transformers for filtering. What’s different is the absence of the single big voltage conversion transformer that defines LF models.

From the outside, it’s usually hard to tell a transformer-based inverter from a transformerless one unless you know what to look for. Many manufacturers don’t label this, and both can have similar casings, displays, and connection points.

That said, there are a few clues:

As for which is more common:

For example:

So, how do these differences translate into performance and capabilities? Let’s take a look:

Transformerless inverters shine in efficiency. Without a large transformer, or by replacing it with a smaller, high-frequency version, they avoid losses from magnetization, copper resistance, and core hysteresis. Many HF models hit 95–98% efficiency. LF models often run 90–95%.

A few percentage points may not sound huge, but over years of use it can add up to massive power savings.

Both LF and HF inverters can produce clean sine-wave AC for sensitive electronics. LF designs naturally filter high-frequency noise by its transformer. HF inverters use digital modulation and advanced filtering to do the same. High-quality units from either type keep total harmonic distortion (THD) under 5%, which is safe for most electronics.

If you’re not sure why sine wave quality matters, check out our pure sine vs modified sine inverter guide to see how it impacts performance and equipment lifespan.

Size and weight are where the difference is obvious. A 5 kW LF inverter can weigh 60–70 pounds. That’s often a two-person lift and requires solid mounting.

A 5–6 kW HF inverter can weigh half as much. One person can mount it on a wall. This makes HF inverters ideal for RVs, boats, tiny homes, and anywhere space is tight. Smaller size also lowers shipping costs and frees up room for batteries and other gear.

HF inverters usually cost less to make because they use fewer heavy copper windings and iron cores. Their mass-produced electronic parts also drive prices down.

LF inverters may cost more upfront, but have simpler electronics and proven durability. HF units rely on more complex control systems, which can add to repair complexity if something fails.

As most HF units are newer to the market, their longevity is still not proven. If an HF unit lasts half as long as an LF unit, then the lifecycle cost may even out.

LF inverters excel at surge power. The transformer acts as an energy buffer, letting them deliver two to three times their rated power for a few seconds, enough to start motors or pumps without a voltage drop.

HF inverters used to struggle with surges, but newer models have improved a lot. Many can deliver 1.5–2 times their rated output for several seconds. Some, like the Sol-Ark 12K, can hit surge ratings equal to or better than LF models in real use.

LF designs still handle repeated or extreme overloads more gracefully. HF inverters use precise protection circuits and will shut down quickly to avoid damage.

Reactive loads, like motors, pumps, and some lighting, draw both real and reactive power. They also cause the voltage and current waveforms to shift out of phase.

LF inverters handle this well. Their transformers help manage the phase shift and keep voltage stable even with poor power factor loads. That makes them a good fit for these loads.

HF inverters rely on fast-switching electronics to control phase shift. They handle most modern appliances fine, but heavy inductive loads with poor power factor can reduce efficiency or cause voltage fluctuations. If your system will run big motors often, an LF inverter may be the safer bet.

Reliability remains a top concern for anyone investing in an off-grid or backup power system, where maintenance may be difficult and downtime costly.

LF inverters are proven workhorses. Their simpler design and physical isolation make them more tolerant of voltage spikes and power surges.

HF inverters have improved greatly in the last decade. New semiconductor technology and better protection circuits give them long service life when installed properly.

Nonetheless, the complexity of high-frequency units means that in extremely harsh or mission-critical environments, some users still prefer the brute-force reliability of transformer-based designs. For most residential, RV, or marine applications, however, high-quality transformerless inverters have proven themselves robust and dependable.

Safety in inverter design goes beyond just meeting power needs, it’s about protecting people, equipment, and ensuring your system meets electrical codes. How an inverter handles grounding, bonding, and electrical isolation can make the difference between a safe installation and a dangerous one.

Galvanic isolation is a core safety feature that separates the input (DC/battery) side of an inverter from the AC output.

Pro Tip: In marine applications, isolation isn’t just about safety, it can also prevent corrosion from stray currents in the water. For a deeper dive into why transformers matter on boats and how they work, check out our guide to marine isolation transformers.

In North American residential and RV systems, proper bonding of the AC neutral to ground is a critical safety requirement.

Improper bonding can trip GFCIs, create stray voltage, or cause unsafe conditions with shore power or generators. Always follow the manufacturer’s instructions and local codes.

From a general user perspective, a well-designed system of either type should operate safely. However, the HF systems have more complexity in implementation, increasing the chances of something going wrong.

| Category | Transformer-Based (LF) | Transformerless (HF) |

| Efficiency & Power Quality | ❌ Lower efficiency (90–95%) ✅ Excellent noise filtering from transformer | ✅ Higher efficiency (95–98%) ✅ Advanced filtering keeps THD <5% |

| Size, Weight & Installation | ❌ Heavy & bulky (5 kW = 60–70 lbs) ❌ Often two-person install | ✅ Lightweight & compact (often <35 lbs) ✅ One-person wall mount |

| Cost | ❌ Higher upfront cost ✅ Proven long lifespan | ✅ Lower purchase price ❌ Lifespan not as proven; may even out in lifecycle cost |

| Surge Power & Overload | ✅ Outstanding surge (2–3× rated) ✅ Handles repeated overloads | ✅ Much improved surge in modern units (1.5–2× rated) ❌ Shuts down faster if overloaded |

| Reactive Load Handling | ✅ Handles motors & poor power factor loads smoothly | ❌ Can lose efficiency or trip offline with heavy inductive loads ✅ Works well for most modern appliances |

| Reliability & Ruggedness | ✅ Extremely durable & tolerant of abuse ✅ Great for harsh conditions | ✅ Reliable with proper install ❌ Less rugged in extreme or mission-critical use |

| Safety, Isolation & Neutral-Grounding | ✅ Built-in galvanic isolation ✅ Simple, safe neutral-ground bonding | ❌ Usually no transformer isolation ✅ UL 1741 models add protections ❌ Bonding more complex; GFCI issues possible |

Choose a transformer-based (LF) inverter if you:

Choose a transformerless (HF) inverter if you:

Pro Tip: Inverter sizing isn’t just about running watts, surge loads matter too. Learn more in our inverter sizing guide.

Advances in semiconductors made high-frequency inverters possible. LF inverters used to rely on silicon MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) and IGBTs (Insulated Gate Bipolar Transistors). These worked well, but couldn’t switch fast enough for high-frequency conversion without losing efficiency.

The game-changer was the arrival of wide-bandgap materials like silicon carbide (SiC) and gallium nitride (GaN). These can handle higher voltages, higher temperatures, and much faster switching than standard silicon.

A SiC MOSFET can switch hundreds of thousands of times per second with very little heat (more efficiency). That lets HF transformerless inverters deliver high power in a much smaller, lighter design. It also cuts energy losses and improves performance in continuous-duty systems.

HF transformerless inverters are gaining market share fast in solar, RV, and off-grid systems. Their lightweight, small size, and high efficiency make them the go-to choice for many new installations.

LF transformer inverters still hold strong in heavy-duty and niche applications where surge power, isolation, or durability are essential.

As semiconductor technology improves, HF inverters will keep closing the gap in surge handling and ruggedness while staying ahead in efficiency and convenience.

Your inverter is the heart of your off-grid or mobile power system. Choosing the right type means matching it to your loads, space, and safety requirements.

At Battle Born Batteries, we offer both transformer-based and transformerless inverters—all UL tested—and can help you select the best one for your setup. Our technical team can guide you through sizing, compatibility, and safe installation so you can power your adventures with confidence.

We know that building or upgrading an electrical system can be overwhelming, so we’re here to help. Our Reno, Nevada-based sales and customer service team is standing by at (855) 292-2831 to take your questions!

Also, join us on Facebook, Instagram, and YouTube to learn more about how lithium battery systems can power your lifestyle, see how others have built their systems, and gain the confidence to get out there and stay out there.

Shop Best Sellers

Ask a technical specialist now at 855.292.2831

Stay in the Know