MENUMENU

TALK TO AN EXPERT

Special Hours: 7AM – 6PM PST

TALK TO AN EXPERT

Special Hours: 7AM – 6PM PST

As Featured on FleetOwner: https://www.fleetowner.com/perspectives/ideaxchange/article/21279212/its-cold-outside-how-do-your-hotel-load-batteries-perform

As winter tightens its icy grip, trucking fleet managers across the country face a familiar challenge: keeping their hotel load batteries operational in frigid temperatures.

While lead-acid batteries have long been the industry standard, their notorious performance decline in colder climates leaves fleets vulnerable to downtime and costly maintenance. In this harsh reality, lithium iron phosphate (LiFePO4) battery technology emerges as a game-changer, offering better performance and reliable power in even the most demanding winter conditions.

Lead-acid batteries have been the standard for hotel load applications for decades. However, their performance suffers significantly in cold weather. As temperatures drop, the internal resistance of the battery increases, leading to several critical issues:

See also: Nikola says battery fix might need design change

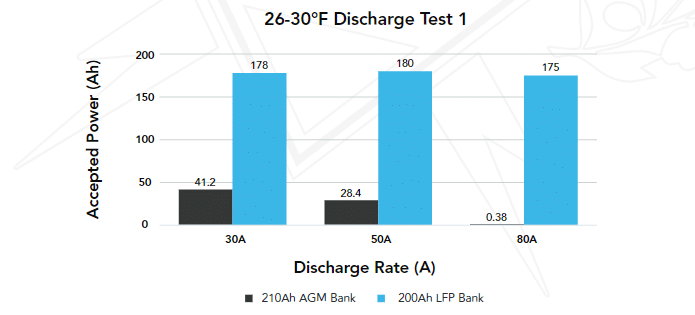

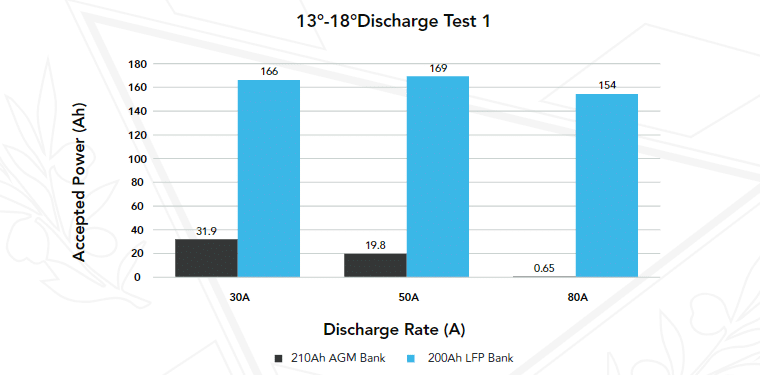

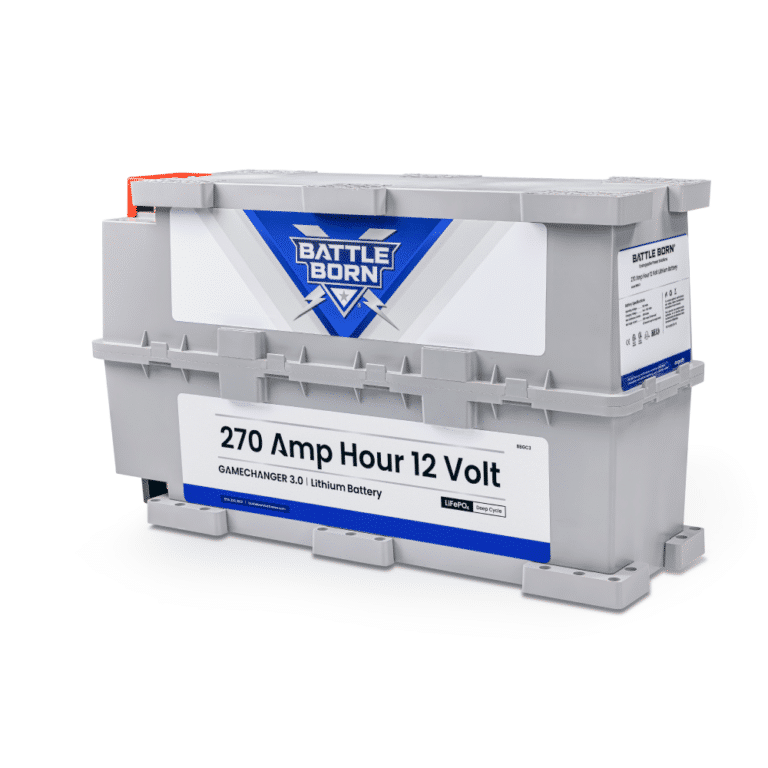

The numbers tell the story themselves: Lead-acid batteries have proven to be unreliable when the weather turns cold. A whitepaper study conducted by Dragonfly Energy, maker of Battle Born Batteries, a brand of LiFePO4 batteries, paints a stark picture of the limitations of lead-acid technology. The study compared the performance of AGM lead-acid batteries to LiFePO4 batteries at various temperatures, ranging from a comfortable room temperature of 72 degrees F down to a winter-like temperature of 13 degrees. The results were clear.

At 26-30 degrees, the LiFePO4 battery bank delivered an average of 89% of its rated capacity between a discharge rate of 30A-80A, while the lead-acid battery bank delivered only an average of 11%.

At 13-18 degrees, the LiFePO4 battery bank still delivered an average of 82% of its capacity between a discharge rate of 30A-80A, while the lead-acid battery delivered only an average of 8%.

These findings have significant implications for trucking fleets, particularly during harsh winter months. Hotel load batteries are vital in powering essential equipment, including HVAC systems for temperature control, food refrigeration for meal storage, and entertainment devices for driver comfort and relaxation during rest periods. When these batteries falter in cold weather, the consequences can be dire. Drivers may face uncomfortable, even unsafe conditions due to inadequate heating or cooling, spoiled food because of malfunctioning refrigeration, and limited entertainment options during their downtime. This can contribute to fatigue, decreased productivity, and, ultimately, safety concerns on the road.

Furthermore, compromised hotel load batteries in cold weather can instill costly downtime and repairs. When batteries cannot provide sufficient power, drivers are often forced to rely on idling their trucks to maintain essential functions. This practice not only consumes excessive fuel, impacting operational costs significantly, but also limits parking opportunities due to the recent increase in anti-idling laws in several regions. Anti-idling regulations aim to reduce pollution and promote sustainable practices, further incentivizing fleets to find alternative “green” solutions for powering hotel loads.

By replacing lead-acid batteries with LiFePO4 alternatives, fleets can gain a significant edge in winter reliability. LiFePO4 batteries offer several key advantages, including:

Embracing the benefits of LiFePO4 batteries emerges as a strategic decision for trucking fleets. The performance of this lithium technology compared to lead-acid in cold weather ensures reliable operation of essential equipment, contributing to driver comfort, safety, and compliance with anti-idling regulations.

As Chief Revenue Officer, Wade Seaburg leads Dragonfly Energy’s sales, business development, and revenue growth and diversification efforts. He is an industry veteran who has proven long-term success serving high-volume OEMs across various markets. Most recently, Seaburg used his diverse skill set to bring valuable power solutions to the heavy-duty trucking industry and introduce the Battle Born All-Electric APU, a custom solution built to provide ample power for trucking hotel loads.

Shop Best Sellers

Ask a technical specialist now at 855.292.2831

Stay in the Know