MENUMENU

TALK TO AN EXPERT

Special Hours: 7AM – 6PM PST

TALK TO AN EXPERT

Special Hours: 7AM – 6PM PST

Heavy-duty trucking is the lifeblood of the global economy, as countless essential goods are transported every day. For long-haul truckers, multiple days on the road require spending nights in the sleeper cabs of their rigs. With limited power options, many truckers rely on idling their engines and antiquated lead-acid batteries to power necessary electronics through the night. Striving to increase truck driver comfort and reduce the carbon footprint of their fleets, trucking companies across the nation are turning to an innovative power solution. Advanced all-electric auxiliary power units are revolutionizing the heavy-duty trucking industry.

As a vital piece of the global economy, challenges facing the heavy-duty trucking industry have far-reaching consequences. Over 70% of all freight in the United States is moved through trucking. People and businesses rely on trucks to deliver consumer goods, medicine, raw materials, and more every day. With the abundance of long-haul trucks on the roads, it’s more important than ever to ensure the comfort of drivers and pursue sustainability.

The heavy-duty trucking industry is facing challenges with the energy sources used in sleeper semi-trucks. Relying predominately on diesel powered systems has created significant environmental, economic, and regulatory problems. As fuel prices remain volatile, greenhouse gas emissions continue to rise, emission regulations become more stringent, and the industry desperately needs an innovative power solution.

Many sleeper semi-trucks are equipped with everything necessary to keep drivers safe and comfortable when they pull off for the night. To keep drivers and the public safe, there are government-mandated rest periods during long-haul drives. These cabs are usually equipped with an air conditioner and heating system, a refrigerator and microwave, a coffee maker, and even satellite internet for TVs, laptops, and gaming systems.

A strong power source is needed to run these electronics for extended periods of time. Each power solution attempts to reach the root of the problem but leaves something to be desired. With multiple semi-truck power options for “hotel loads” on the market right now, some concerns still aren’t being addressed. There are 11 key market drivers for a new, long-haul power solution.

One of the simplest ways to power the various electronics in sleeper cabs is by idling the engine throughout the night. While effective, this solution consumes an excessive amount of fuel. Idling a sleeper cab semi-truck can consume about 0.8 to 1 gallon of diesel per hour. For drivers who idle overnight or during rest periods, this can amount to 8-10 gallons per night.

In addition to increased fuel consumption, prolonged idling can lead to increased engine wear and tear. This excess strain results in more frequent maintenance, an increased likelihood of mechanical failures, and a shorter engine life.

The noise and vibration of an idling engine can be detrimental to both truck drivers and residents of the areas they stop in. Auto start and stop can disrupt truck driver sleep and impact their health and alertness. Additionally, when truck drivers pass through urban and residential areas, idling can be a nuisance to residents and lead to strained community relations.

As environmental concerns rise to the forefront of consumers, corporations, and government officials’ minds, many trucking companies are seeking ways to minimize their carbon footprint. Engine idling leads to unnecessary emission of greenhouse gases (GHGs) and pollutants like Nitrogen oxides (NOx) and particulate matter (PM), contributing to air pollution.

Lead-acid batteries used for engine starting and other power solutions must be replaced frequently and have limited disposal options. With only 5 smelters in the US available for recycling these batteries, the process is energy-intensive, and extensive time and cost are required when swapping batteries.

When relying on lead acid batteries to power electronics, it’s essential to closely monitor their state of charge to avoid extensive damage. Most of these batteries can only be discharged to 50% capacity before the user runs the risk of permanent damage to the life cycle.

Utilizing engine idling to power hotel loads is an inefficient use of energy. Since diesel engines were designed for propulsion and not power generation, the fuel-to-energy conversion is extremely inefficient. Additionally, the added weight of lead-acid batteries negatively impacts the truck’s fuel efficiency and payload capacity.

If truck drivers will be traveling through extreme cold or hot temperatures, their lead acid batteries will be less reliable and efficient. Their inability to function to their full potential in extreme weather can severely inhibit drivers from being able to power their necessary hotel loads during rest periods.

Without advanced battery management systems (BMS), lead-acid batteries must be manually monitored to maintain their health and the drivers’ safety. There is no way to remotely monitor the battery’s health, temperature, and charge level.

Some regional governments are offering incentives and subsidies for adopting green technologies to encourage trucking companies to pursue sustainability and reduce their carbon footprint.

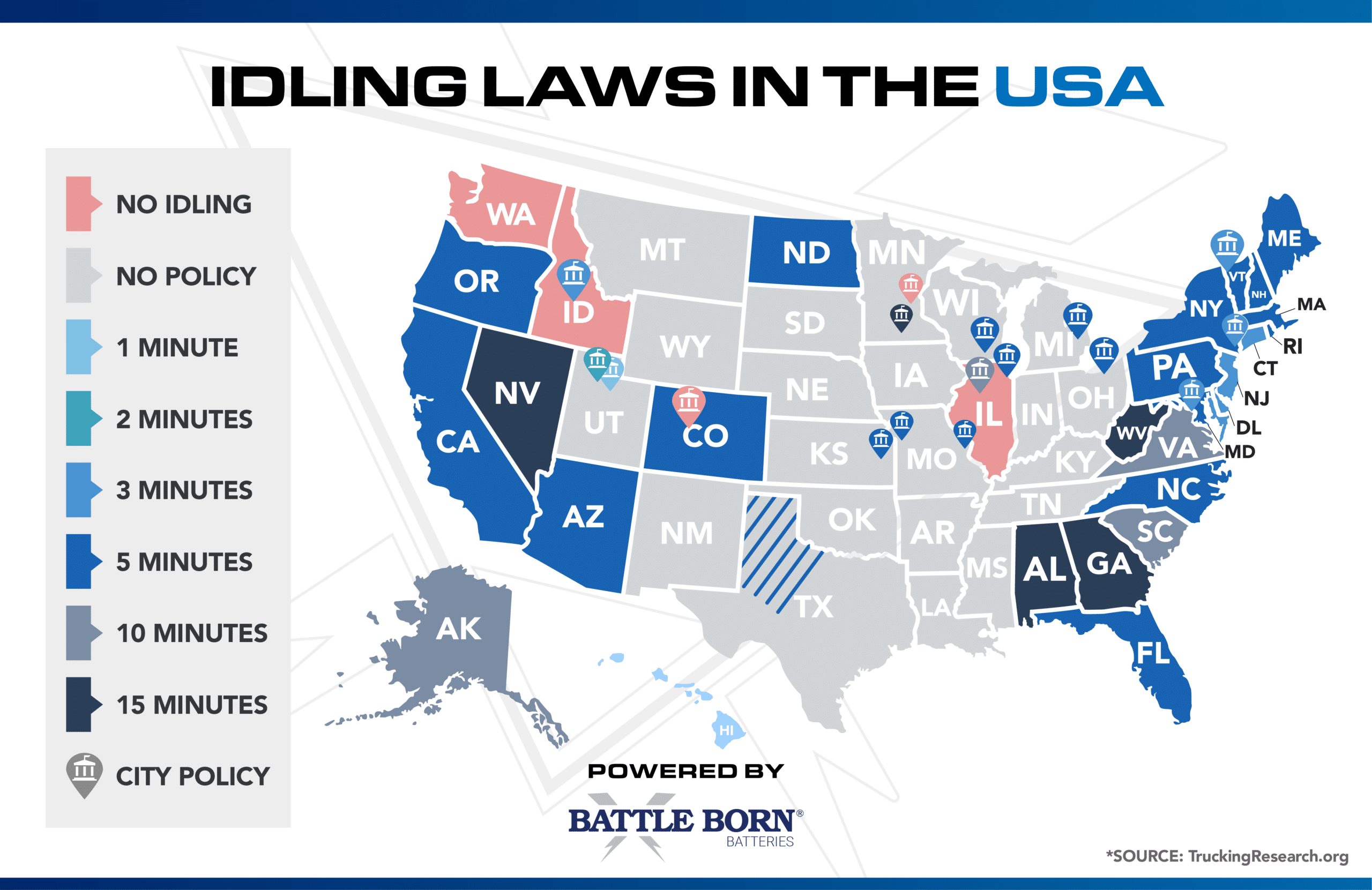

Similarly, these companies are facing both federal regulations and self-implemented ESG goals. As anti-idling laws grow in popularity, truck drivers are running into legal compliance issues with how they power their hotel loads. Limiting emissions will allow them to comply with regulations and minimize the negative health and environmental implications of these antiquated practices.

Although many truck drivers are used to relying on engine idling to power their electronics through the night, this practice is no longer a practical option. In addition to excessive costs due to increased fuel consumption and engine maintenance, the negative consequences of this practice are far-reaching. Long-term idling has a lasting negative impact on both the environment and the health of drivers and communities. To reduce the need to idle, various power solutions have been implemented over the last few years with varying degrees of effectiveness.

Initially, engine auto start/stop was suggested to minimize trucks’ time idling. These systems allowed the engine to automatically shut off when power wasn’t needed and then automatically restart again to power essential electronics. While this solution has been proven to conserve fuel and reduce emissions, it only works in very specific situations. Truckers facing extreme weather conditions may continue to constantly idle as power is needed throughout the duration of the rest period to keep up with air conditioning and heating systems.

The next option was diesel auxiliary power units (APUs), which would eliminate the need for truck idling. By running independently, they provide power and climate control without the truck engine operating, resulting in fuel savings and reduced emissions. However, these units come at a substantial cost to drivers and companies. Initial investment ranges from $8,500 to $13,000. Additionally, fuel consumption, necessary oil changes, and other maintenance lead to continued expenses throughout the life of the unit. Not to mention that the diesel consumption of these APUs produces exhaust emissions that contribute to air pollution.

Finally, electric APUs powered by AGM batteries were introduced. These units eliminate engine idling and provide independent power without consuming excess diesel. Electric APUs produce zero exhaust emissions, contributing to a cleaner environment. While this may seem like the perfect solution, these APUs are limited by the AGM batteries that power them. With limited energy density, higher weight, and lackluster reliability, this solution still leaves something to be desired.

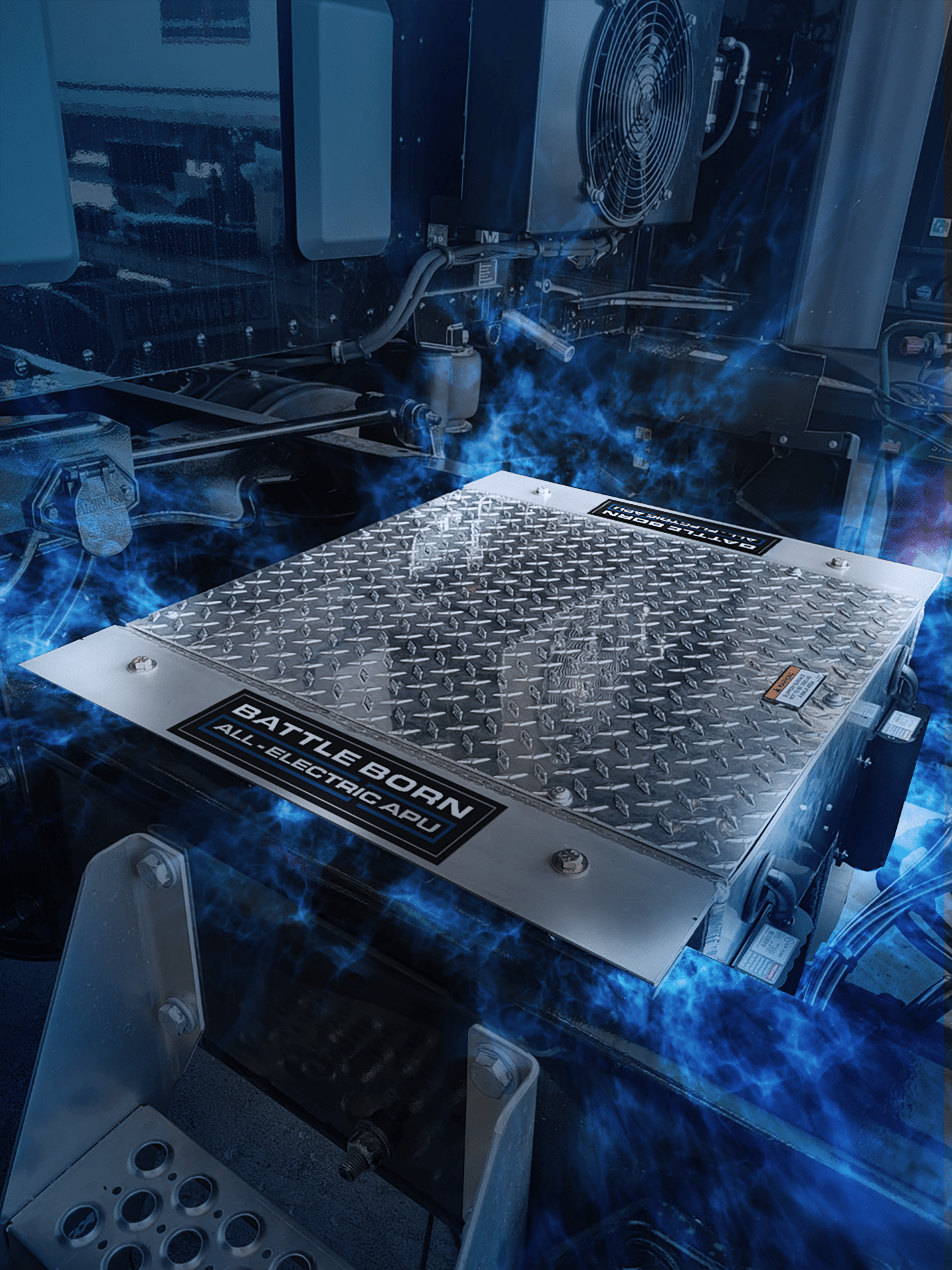

With the increasing need for a new power solution for long-haul truck drivers, the trucking world has turned to lithium-ion technology. Trucking companies and owner-operators have begun adopting advanced all-electric lithium-ion auxiliary power units (APUs) to power the hotel loads of sleeper cab semi-trucks.

The transition to lithium-based APU systems presents a significant opportunity for the trucking industry to save billions of dollars on fuel costs, reduce harmful emissions during idle rest periods, and enhance sleeper cab driver comfort. Utilizing the power of industry-leading Battle Born Batteries, these units have ample capacity for an extended runtime of appliances and amenities. With a substantial increase in power capacity over AGM units, the runtime for 12V air conditioning doubles, keeping drivers comfortable in any condition.

Battle Born Batteries All-Electric APU system separates the auxiliary power system from the starting batteries, creating a “house bank” for hotel loads. This lithium system provides a low Total Cost of Ownership (TCO) in the market, ensuring long-term savings for trucking companies and drivers. The quick Return on Investment (ROI) makes this system an attractive solution for enhancing the power capabilities of sleeper cabs. With far-reaching cost savings, not only does this solution eliminate excessive fuel consumption and costly maintenance, but it also improves overall driver satisfaction, leading to higher rates of driver retention.

When trucking companies transition their fleets to all-electric power, they experience a wide range of benefits. First and foremost, the high energy density of lithium batteries ensures more power storage with less weight, and efficiency is key for more extended operational periods between charges. Additionally, the high energy density helps in terms of weight and space considerations. These systems aim to minimize weight while maximizing fuel efficiency and payload capacity. Upgrading to an all-electric APU eliminates thousands of pounds of lead acid batteries over the lifetime of the truck.

The process of upgrading a semi-truck sleeper cab with new power should be a simple and hassle-free process. All-electric lithium-ion APUs have been designed to be compatible with existing truck systems. They should seamlessly integrate with the truck’s electrical and power systems without requiring extensive modifications. These APUs also have extensive durability and reliability in various operating conditions, giving drivers peace of mind no matter what they encounter on the road. Drivers can also rest assured, knowing that they have plenty of power for all their appliances. An all-electric lithium-ion APU will provide reliable heating, cooling, and electronic power, enhancing the driver’s rest and overall job satisfaction.

All electric power systems do far more than provide more efficient power and comfort to drivers. They also significantly reduce emissions compared to diesel APUs, aligning with environmental regulations and sustainability goals. New regulations and restrictions on idling and other CO2 emissions are encouraging trucking companies to pursue green power solutions. An all-electric lithium-ion APU solution removes the need to idle and heavily reduces a trucker’s carbon footprint.

Finally, these units provide significant cost savings throughout the lifetime of their use. Even considering the initial investment, all-electric lithium-ion APUs have the power to substantially reduce operating costs. With fuel savings, reduced maintenance costs and downtime, and available subsidies and incentives for adopting cleantech technology, these units benefit the bottom line.

The Battle Born Batteries All-Electric APU system is prepared to revolutionize the heavy-duty trucking industry. Having secured pilot programs with fleets representing roughly 15 percent of the North American heavy-duty trucking market, Dragonfly Energy is leveraging its experience with hundreds of thousands of systems in adjacent markets. Leading the way for sustainability, this unit will help fleets reduce downtime, increase driver retention, and achieve key sustainability goals.

At Battle Born Batteries, we’re ready to partner with you on your mission to improve your fleet’s performance today. Our Battle Born All-Electric APUs are designed to power your fleet’s hotel loads more efficiently and sustainably than ever before. Look at how these units are helping trucking companies cut fuel costs, reduce emissions, and enhance driver comfort in our latest whitepaper, Powering the Long-Haul: Transforming Semi-Truck Sleeper Cabs with Advanced All-Electric Auxiliary Power Solutions.

Shop Best Sellers

Ask a technical specialist now at 855.292.2831

Stay in the Know